This is not a valid variable product.

Each product needs a distinct packaging style to help it stand out. To meet this need, we provide a range of packaging styles, including:

Packaging Layers aims to give its customers freedom, which is why we offer a range of customization options.

Custom lip liner boxes are special packages made just for lip liners. They help sellers stand out, keep their products safe, and show off their brand better than regular boxes, which can be boring and not fit the product well.

Packaging Layers was started with a single purpose: to help American businesses increase their sales. We offer unique services that set us apart from others in the industry, providing American businesses with up to a 40% discount on their first order. This initiative aims to encourage small businesses and allow them to experience the magic of custom boxes.

Getting the 40% discount is straightforward. You simply need to call us and inform us that this is your first collaboration with Packaging Layers. After that, our sales team will apply the 40% discount on your final invoice. Alternatively, if you prefer to receive a discount quote through a form, just fill in all necessary details and enter “PL 40%” in the requirements section. Our team will then provide you with an instant quote reflecting the 40% discount.

We have a question for you, and we want you to answer honestly. Do you also feel that your lip liners are better than your competitors’? If yes, then why are your sales lower than theirs?

There is one reason that you may not have considered, but it is benefiting your competitor: the packaging of your lip liners. Remember, before using your product, customers first see the packaging, which influences their perception of the quality of the lip liners inside.

To address this issue, Packaging Layers offers custom packaging for lip liners. With custom box lip liners, you can easily capture customers’ attention and ensure that when they see your lip liners, they want to purchase them on the spot.

We use advanced printing technology to bring your designs to life. Additionally, we offer many customization options that we can discuss later. If you want the best return on your investment, just keep reading. If you’re short on time or can’t read through everything, don’t worry! Just give us a call, and our customer support and sales team will understand your needs and create an excellent design for your lip liners.

Although packaging is very important for any business, it cannot be ignored when it comes to the lip liner business. This is because customers judge the quality of lip liners based on their packaging. Therefore, we offer custom lip liner box packaging.

These personalized lip liner pencil boxes allow lip liner businesses to showcase images of their lip liners on the boxes, as well as display ingredients, benefits, necessary guidelines, and much more.

Including all these essential elements can help win customer trust, and customers tend to remain loyal to companies they can trust.

When a lip liner business approaches us, they often think that custom packaging is just another expense with no real benefit.

However, this perception is completely wrong. Such views are typically held by businesses that do not understand the advantages of customized lip liner packaging. Once lip liner businesses order our packaging and observe an increase in sales and repeat customers, they come back to reorder because our custom lip liner boxes prices are quite affordable.

Many businesses have told us that investing in custom packaging has been their best investment to date. You can gauge the satisfaction of lip liner businesses through our customer testimonials, which reflect their happiness in collaborating with us.

A lip liner business aims to create lip liners that are superior to its competitors, and to achieve this dream, Packaging Layers has introduced custom lip liner boxes USA. These boxes can be tailored exactly to your specifications. You can print your logo, design, lip liner images, slogans, brand name, or anything else you desire on them.

The advantage of using these custom printed lip liner boxes is significant: when a customer enters a retail shop, their first glance will fall on your lip liners, which will be in unique printed boxes, while competitors’ lip liners will be in standard packaging.

This visual distinction can lead customers to choose your lip liners over others. Over time, as customers become familiar with your packaging, they will recognize your brand even when shopping online and are likely to order from you, resulting in increased sales for your business.

Packaging Layers offers custom-made lip liner boxes in various sizes to accommodate the diverse types of lip liners available. Understanding the need for efficient packaging, we provide both assembled and flat boxes for shipping. This approach not only saves space for businesses but also simplifies storage and assembly, with boxes that can be put together in under ten seconds, potentially reducing labor costs significantly.

Some of our best selling lip liner box dimensions are:

In response to the growing focus on sustainability, Packaging Layers has introduced eco-friendly lip liner packaging. Their sustainable lip liner boxes are made from kraft material that is both FDA and FSC certified, aligning with consumer preferences for brands that prioritize environmentally friendly practices. This initiative aims to ensure that customers choose brands that utilize sustainable packaging, helping clients retain their customer base against competitors.

If you prefer a minimalist lip liner packaging then we also offer lip liner boxes is single color such as:

|

| ||

| Dimensions | All Custom Sizes & Shapes | ||

| Quantities | No Minimum Order Required | ||

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock | ||

| Printing | No Printing, CMYK, CMYK + 1 PMS color, CMYK + 2 PMS colors | ||

| Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling | ||

| Included Options | Die Cutting, Gluing, Scored, Perforation | ||

| Additional Options | Eco-Friendly, Recycled Boxes, Biodegradable | ||

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) | ||

| Turnaround | 4 – 8 Business Days, RUSH | ||

| Shipping | FLAT |

A-Flute offers strong protection and great stacking strength for secure packaging needs always.

B-Flute provides a smooth surface ideal for printing and precise die-cutting processes always.

C-Flute balances crush resistance, stacking strength, and printing quality moderately well always.

E-Flute features a flat surface perfect for high-quality printing applications always used.

F-Flute is used for specialty packaging and small retail displays effectively always.

Bleached white board with vibrant finish for bright, professional-looking printed packaging solutions.

Coated semi-gloss board with brilliant white surface for sharp, high-quality printed designs.

Uncoated, unbleached kraft board made from mixed virgin/recycled pulp for eco-friendly packaging needs.

Coated, textured lineboard with off-white surface for premium print quality and visual appeal.

Black-dyed kraft paper coated both sides for printing and packaging uses.

Recycled paperboard with a white surface for high-quality printing needs.

Kraft paper with a coated top and uncoated bottom for versatile printing.

Kraft paper with an uncoated bleached top and unbleached bottom side.

Recycled paperboard coated on one side for eco-friendly printing options.

Special paper featuring a glossy or matte holographic finish for unique effects.

Special paper with a glossy or matte metallic finish for luxury packaging.

Kraft paper with a mix of pulp, coated both sides for printing purposes.

Premium white paperboard, coated on one side for excellent printing and finishes.

White paperboard coated on both sides for high-quality printing and finishes.

Textured paper stock used for wrapping rigid boxes with a premium feel.

Uncoated kraft paper made from mixed pulp for basic packaging needs.

Bleached kraft paper with both sides coated for printing and packaging.

A recessed impression is made by pressing dies on the front of the material without ink or foil.

A raised pattern is formed without any ink or foil by pressing dies on the material’s back.

Foil is applied to a surface using UV adhesives without heat, offering a quick and cost-effective method.

This combines embossing and foil stamping to produce a raised design with a metallic finish.

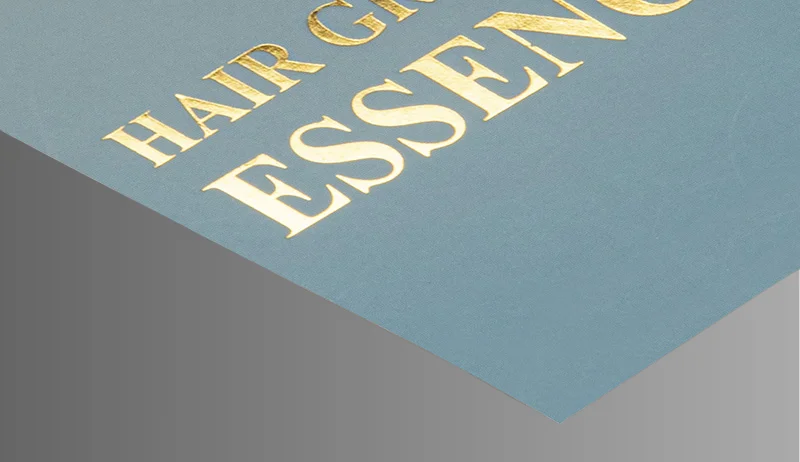

This technique transfers metallic or colored foil onto a surface using heat and pressure. It creates shiny,

A raised design is created by pressing a die on the back of the material, forming a 3D effect.

A die-cut shape is covered with transparent film to create a window that reveals the product inside.

Digital printing is cost-effective for small runs, transferring designs electronically without plates needed.

Offset printing uses plates and rubber blankets for high-quality large print runs efficiently always.

Oil-based ink provides high-quality colors but is not eco-friendly due to oil content used.

Pantone Metallic uses specific formulas to print precise metallic colors consistently every time.

Pantone ensures precise color printing using specific ink formulas consistently every time.

Soy ink is eco-friendly, using soy or vegetable oils for vibrant color outputs always.

UV printing uses ultraviolet light to dry ink fast, creating a glossy finish always.

Water-based ink is eco-friendly, using water and pigment for high-quality color outputs always.

Anti-scratch Lamination is a cost-effective option resistant to scratches and fingerprints.

Aqueous coating is a clear, fast-drying, eco-friendly option with gloss or matte finishes available.

Lamination adds a protective film to packaging for maximum durability and protection.

Soft Touch Coating creates a velvety texture for a tactile feel on packaging materials.

Soft Touch Lamination offers a satin or matte finish with a soft, peach-like texture.

Spot Gloss UV applies a shiny finish to specific areas using ultraviolet light curing.

UV coating is a fast-drying finish cured with ultraviolet light, available in gloss or matte.

Varnish is a clear coating applied using CMYK printing, available in gloss, satin, or matte.

At Packaging Layers, we specialize in creating tailored packaging solutions that meet your unique needs. From innovative designs to efficient delivery, we handle every step with care and precision to bring your ideas to life.

We've covered all the frequently asked questions you might have before placing your custom printed box order.

No, you don’t need to pay for plates or die charges, nor do you need to pay for shipping or design services. Whatever price is on the invoice we send you will be final, and there will be no extra hidden charges.

Yes, you can print inside any custom printed box.

Yes you can print your own artwork but before that you have to get in touch with our designer so that they can update you regarding format and resolution requirements.

You can order as low as 10 custom boxes and 100 custom bags.

Your shipping duration entirely depends on the method you choose at checkout. If you opt for rush delivery, your order will reach your doorstep within 4 to 6 working days.